How is SAP used in manufacturing?

What is SAP Manufacturing?

SAP Manufacturing solutions enable your company to integrate and embed intelligence in processes facilitating Industry 4.0 principles with a single-source of real-time information. They provide the data required for optimal coordination of resource planning and production execution, covering all aspects of the manufacturing cycle from production order to order fulfilment and beyond. Digitization of your manufacturing processes allows you to increase manufacturing efficiency and agility and leverage the Industrial Internet of Things (IIoT). Furthermore ensures transparency at the component and material level at all times. How is SAP used in manufacturing?

SAP is the only company that provides a fully integrated solution from machine level to ERP all-in-one. If your company is already running on SAP S/4 HANA and you are looking to fully integrate your supply chain and get more out of your production, SAP offers a variety of solutions for digital manufacturing.

Digital Manufacturing with the SAP Manufacturing Suite

The modular structure of the SAP Manufacturing Suite powered by SAP Leonardo allows you to scale a solution tailored towards your specific needs. Whether your needs range from basic MES functionality with a focus on effectively controlling work-in-progress (WIP) processes, to “paperless manufacturing” by automating communication and decision-making regarding the execution of production processes, to more advanced automation capabilities where the operator oversees production processes which execute through limited or no human intervention – it is possible to identify the modules, methods, and products necessary to meet the unique needs of your production environment.

- SAP Manufacturing Execution (SAP ME)

SAP ME is a complete, configurable MES system for discrete manufacturing that enables you to manage and control and production operations. - SAP Manufacturing Integration and Intelligence (SAP MII)

SAP MII is the proven solution for the process industry. In addition to being able to monitor production in near real-time, it offers extensive data analysis tools. Data from a wide range of systems can be integrated, combined with data from business systems and necessary actions can be executed automatically or manually. - SYSTEMA’s SAP Accelerator Suite (MAX Suite)

SYSTEMA’ Accelerator Suite is a rapidly deployable, modular solution that can be quickly implemented to provide MES-like services. - SAP Plant Connectivity (SAP PCo)

SAP PCo enables data transfer between production level with SAP Execution Systems (MES) and ERP. - SAP Digital Manufacturing Cloud (DMC)

SAP DMC, improves with near real-time data and analytics. Execute manufacturing processes, analyze manufacturing and business data, and integrate systems with a cost-effective, high-quality, and resource-efficient method based on Industry 4.0. - SAP HANA Cockpit

SAP HANA Cockpit ensures IT systems’ availability and optimizes computing power. - SAP OEE Package Solutions

Overall equipment effectiveness (OEE) measures of the true performance of manufacturing productivity by evaluating equipment availability, production performance, and product quality factors.

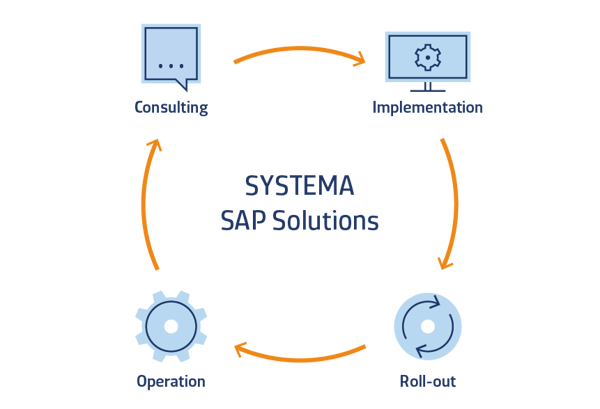

SAP Manufacturing Consulting and Services

- Analysis and optimization of manufacturing processes

- Architecture and process consulting for manufacturing execution solutions

- Design and implementation of automation solutions

- Integration of standard SAP MES solutions

- Customized extensions for SAP MES solutions

- Equipment integration services (more than 10,000 equipment integrations worldwide)

- Execution of international projects from small to large scale

- Support for SAP MES implementations with 24/7 support operating 365 days a year