This is the COMPLETE SAP ERP modules list.

SAP ERP modules and SAP ERP components are the same thing (SAP changed the name in 2004—more on this below).

Get the full list of SAP ERP modules and learn what they are with this detailed article.

So without further ado, let’s do this!

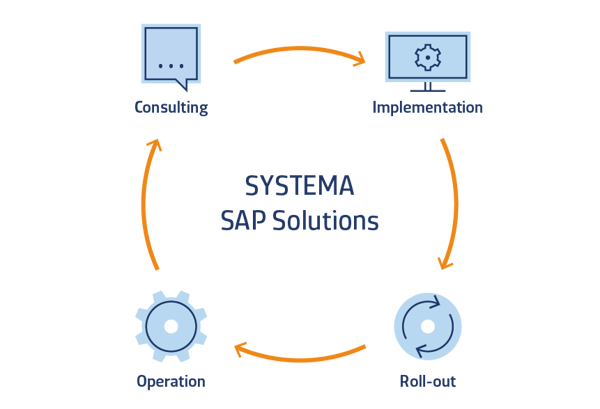

Imagine SAP ERP modules (now SAP components) as building blocks for SAP ERP (Enterprise Resource Planning) systems, such as:

- SAP R/3 (SAP Real-Time Tier 3)

- SAP ECC (SAP ERP Central Component)

- SAP S/4HANA (SAP Business Suite 4 SAP HANA)

A company picks the building blocks to integrate into their SAP ERP system that it needs and leaves out the ones that aren’t needed.

Each building block provides technology to run other building blocks or functionality for a specific purpose such as:

- Finance

- Human Resources

- Logistics

SAP ERP modules allow you to break your SAP ERP system into simpler and more manageable parts. SAP NetWeaver is both the technical foundation for the building block and a building block.

Although SAP ERP modules are now called SAP ERP components (since 2004 with the SAP R/3 upgrade to SAP ECC), for the sake of the old days and because modules sound cooler than components (don’t you think so too—leave a comment), let’s just call them SAP ERP modules.

Below SAP ERP Modules vs. SAP ERP Components, you’ll find a detailed explanation of the differences between SAP ERP modules and SAP ERP components.

First, let’s look at the difference between technical and functional SAP ERP modules:

SAP ERP modules come in two flavors:

- Technical SAP ERP modules

- Functional SAP ERP modules

Technical SAP ERP Modules

Technical SAP ERP modules make up the technical foundation of an SAP ERP system.

Technical SAP ERP modules are needed to integrate the functional SAP ERP modules.

Technical SAP ERP modules contain NO logic but serve as the environment for running functional SAP ERP modules.

Two technical SAP ERP modules are mandatory:

Functional SAP ERP modules are building blocks that contain the processes and logic of specific business areas.

Functional SAP ERP modules extend an ERP system with functionality for certain business areas.

For example, three functional SAP ERP modules are:

- CO (Controlling)

- FI (Financial Accounting)

- PM (Plant Maintenance)

SAP ERP Submodules

SAP ERP modules are further divided into SAP ERP submodules.

SAP ERP submodules provide additional functionality in the business area of their parent.

For example, the SAP ERP module SAP PLM (Product Lifecycle Management) offers the SAP ERP submodules:

- Basic Data for Process Manufacturing

- Classification

- Document Management

- Engineering Change Management

- Enterprise Content Management

Even though SAP ERP modules are software, they are not software in a computer science sense in terms of programming.

In computer science, a software module is a functional and self-contained unit of software consisting of processing steps and data structures.

Though SAP ERP modules have processing steps and data structures. But SAP ERP modules are not functional and self-contained units. Since the functions of SAP ERP modules are intertwined or they rely on each other.

Operating an SAP ERP module always affects other SAP ERP modules. Therefore, SAP ERP modules are not self-contained and are no software modules in terms of computer science.

Maybe this is the reason because SAP changed the name from modules to components to differentiate more clearly between SAP ERP modules and software modules in a computer science way.

First, an overview of:

- All technical SAP ERP modules

- All functional SAP ERP modules

Following is the complete SAP ERP modules list including all SAP ERP modules and their submodules.

Let’s get started:

Here’s the complete list of all technical SAP ERP modules:

- ABAP (Advanced Business Application Programming)

- Basis

- BI (Business Intelligence)

- CA (Cross-Application Components)

- NW (NetWeaver)

Here’s a list of all functional SAP ERP modules:

- CO (Controlling)

- CRM (Customer Relationship Management)

- CS (Customer Service)

- EC (Enterprise Controlling)

- EPM (Enterprise Performance Management)

- EHS (Environment, Health, and Safety)

- FI (Financial Accounting)

- HCM (Human Capital Management)

- IS (Industry Solutions)

- LIS (Logistics Information System)

- MM (Materials Management)

- PLM (Product Life Cycle Management)

- PM (Plant Maintenance)

- PP (Production Planning)

- PS (Project Systems)

- QM (Quality Management)

- SCM (Supply Chain Management)

- SD (Sales and Distribution)

- SEM (Strategic Enterprise Management)

- SRM (Supplier Relationship Management)

- TR (Treasury)

Here’s the full list of all of SAP ERP’s technical modules and their submodules:

ABAP

- ABAP 00

- ABAP Workbench

- ALE

- ALV reporting

- ASAP methodology

- Business Connector

- Business Server Pages

- Business Workflow

- Data Dictionary

- Dialog Programming

- EBP

- EDI

- IDOCS

- Internet Application Server

- LSMW

- Menu Painter

- Mercator Report Painter

- Report writer

- Repository Information System

- SAP Script

- Screen Painter

- Smart forms

Basis

- ABAP Programming & Runtime Environment

- ABAP Workbench

- Application Link Enabling

- Authorization System Monitoring with CCMS Workload Alert Monitor

- Basis Services/ Communication Interfaces

- Business Management

- Change and Transport System

- Client Server Technology

- Common Program Interface Communications

- Computer Aided Test Tool

- Computing Center Management System

- Controls & Control Framework

- Customizing

- Database Interface, Database Platforms

- Documentation & Translation Tools

- Electronic Data Interchange

- Fiori

- Front End Services

- Gateway

- HANA

- Middleware

- Network Integration

- Object Linking & Embedding

- Operating System Platform

- Ready to Run R/3

- Remote Function Calls

- SAPUI5

- Security

- Upgrade General

- BI Platform

- BI Suite—Business Explorer

- Business Objects

- Data Warehousing

- Design Build

- Development Technologies

- Info Cube

- ODS Structures

Cross Application Components (CA)

- Application Link Enabling

- SAP Business Workflow

NetWeaver (NW)

- Application Platform

- Business Information Warehouse

- Business Intelligence

- Enterprise Portal

- Exchange Infrastructure

- Information Integration

- Knowledge Management

- Life Cycle Management

- Master data Management

- Mobile Engine

- People Integration

- Portal Content

- Process Integration

- Security

- Solution Manager

- Visual Composer

- Web Application Server

Here’s the list of all functional SAP ERP modules and submodules.

Controlling (CO)

- Activity Based Costing

- Cost Centre Accounting

- Material Ledger

- Overhead Cost Controlling

- Product Cost Controlling

- Profitability Analysis

- Sales Order Costing

- Split Valuation

- Transfer Pricing

Customer Relationship Management (CRM)

- Channel Management

- CRM Enterprise

- CRM Sales

- E-Commerce

- Field Applications

- Industry Specific CRM

- Interaction Center

- Marketing

- Trade Promotion Management

Customer Service (CS)

- Controlling

- Service Contracts

- Service Processing

- Workflow in Customer Service

Enterprise Controlling (EC)

- Business Planning and Budgeting

- Consolidation (EC-CS)

- Executive Information System

- Profit Center Accounting

Enterprise Performance Management (EPM)

- Corporate Close

- Entity Close

- Planning, Budgeting, and Forecasting

- Profitability and Cost Management

- Reporting and Disclosure

- Strategy Development and Translation

Environment, Health, and Safety (HCM)

- Basic Data & Tools

- Dangerous Goods Management

- Global Label Management

- Industrial Hygiene and Safety

- Occupational Health

- Product Safety

- Waste Management

Financial Accounting (FI)

- Accounts Payable

- Accounts Receivable

- Asset Accounting

- Bank Accounting

- Business Planning and Consolidation (BPC)

- Closing Cockpit

- Consolidation

- Credit management

- Extended Ledger

- Financial Supply Chain Management

- Funds Management

- General Ledger Accounting

- Group Risk and Compliance (GRC)

- Joint Venture Accounting

- Lease Accounting

- New General Ledger

- Real Estate Management

- Revenue Accounting and Reporting (RAR)

- S/4 HANA Finance

- Special Ledger

- Taxes

- Travel Management

Human Capital Managment (HCM)

- Benefits Administration

- Compensation Management

- Incentive

- Information System

- Internet Scenarios

- Organizational Management

- Payroll

- Personnel Administration

- Personnel Development

- Personnel Planning

- Recruitment

- Self-Service

- SuccessFactors

- Talent Management

- Time Management

- Training and Events Management

- Travel Management

- Wages

- Workflow

Industry Solutions (IS)

- Consumer Industries

- Agribusiness

- Consumer Products

- Fashion

- Life Sciences

- Retail

- Wholesale Distribution

- Discrete Industries

- Aerospace and Defense

- Automotive

- High Tech

- Industrial Machinery and Components

- Energy and Natural Resources

- Building Products

- Chemicals

- Mill Products

- Mining

- Oil and Gas

- Utilities

- Financial Services

- Public Services

- Defense and Security

- Federal and National Government

- Future Cities

- Healthcare

- Higher Education and Research

- Regional, State, and Local Government

- Service Industries

- Cargo Transportation and Logistics

- Engineering, Construction, and Operations

- Media

- Passenger Travel and Leisure

- Professional Services

- Sports and Entertainment

- Telecommunications

Investment Managment (IM)

- Appropriation Requests

- Automatic Settlement of Fixed Assets

- Corporation Wide Budgeting

- Depreciation Forecast

- Information System

- Investment Measures

- Investment Programs

Logistics Information System (LIS)

- Inventory Controlling

- Plant Maintenance Information System

- Production Planning and Control Information System

- Project Information System

- Purchasing Information System

- Retail Information System

- Sales Information System

Materials Management (MM)

- Extended Warehouse Management

- External Services Management

- Inventory/Valuations

- Inventory Management

- Invoice Verification

- Logistics (General)

- Logistics Information System

- Materials Planning

- Purchasing

- QM in MM

- Warehouse Management

- Workflow

Plant Maintenance (PM)

- Customizing

- Equipment and Technical Objects

- Information System

- Internet Scenarios

- Maintenance Order Management

- Maintenance Planning

- Maintenance Projects

- PM Processing

- Preventative Maintenance

- Service Management

- Structuring Technical Systems

- Work Clearance Management

Product Life Cycle Management (PLM)

- Basic Data for Process Manufacturing

- Classification

- Document Management

- Engineering Change Management

- Enterprise Content Management

Production Planning (PP)

- Assembly Orders

- Capacity requirements

- Information System

- KANBAN

- Make to Order

- Master Planning

- Plant Data Collection

- PP – Processes

- PP for Process Industries

- Product Cost Planning

- Production Orders

- Repetitive Manufacturing

- Sales and Operations Planning

Project Systems (PS)

- Approval

- Basic Data

- Information System

- Operational Structures

- Project Execution and Integration

- Project Planning

- Results Analysis

- Work Breakdown Structure

Quality Management (QM)

- Certificates

- Control

- Inspections

- Notifications

- Planning

- QM-IS

- Test Equipment Management

Sales and Distribution (SD)

- Billing

- Credit Control

- Electronic Data Interchange

- Foreign Trade

- Internet

- Master Data

- QM in SD

- Sales

- Sales Information System

- Sales Support

- Shipping

- Special Business Transactions

- Transportation

Supply Chain Management (SCM)

- Advance Planning and Optimization

- Event Management

- Forecasting and Replenishment

- Inventory Collaboration Hub

- Product Development and Life Cycle Management

- SCM Basis

- SCM Process and Business Scenarios

Supplier Relationship Management (SRM)

- Catalogue Content Management

- Plan Driven Procurement

- Self Service Procurement

- Service Procurement

- Spend Analysis

- Strategic Sourcing

Treasury (TR)

- Cash Management

- Electronic banking

- Funds Management

- Information System

- Loans Management

- Market Risk Management

- Treasury Management

There you go!

Some SAP ERP Modules Explained

Here are a few SAP ERP modules explained:

SAP FICO (SAP Finance and SAP Controlling)

SAP FICO helps an organization manage its financial data. SAP FICO enables organizations to keep an up-to-date version of their financials. SAP FICO in particular is designed to help companies create and maintain financial statements for analysis and reporting, as well as to assist with effective business planning and decision-making.

SAP FICO is comprised of two parts:

- SAP FI (Finance): handles overall financial reporting and accounting

- SAP CO (Controlling): focuses on cost planning and monitoringSAP FI and SAP CO used to be two separate modules, but now they’re so tightly integrated that they’re just talked about as one module.

SAP HCM (SAP Human Capital Management)

SAP HCM is used for recruiting, managing and developing employees.

HCM focuses on human resources as assets that need to be invested in and managed so they’re maximizing their business value. HCM is more than HR’s administrative functions and includes such strategic roles as talent management and employee engagement.

HCM also refers to the software that’s used to automate processes like development, management, and recruitment.

SAP MM (SAP Materials Management)

SAP MM allows companies to manage materials, inventory, and warehouses. SAP MM’s primary goal is to ensure the organization’s supply chain is always stable by ensuring material is kept in proper quantities and without shortfalls or gaps.

SAP MM also makes it possible for supply chain professionals and other SAP users to complete their purchases more quickly, and in a cheaper and more efficient manner, and to keep up with changes in these processes.

SAP MM is a part of logistics, and it helps manufacturers with their supply chains.

SAP PM (SAP Production Maintenance)

SAP PM helps companies maintain and support their equipment and systems.

SAP PM has three components to help with maintenance:

- Inspections: determines the actual condition of the system or equipment.

- Preventive maintenance: helps ensure optimal conditions for systems or equipment.

- Repair: supports the restoring of systems or equipment.

SAP PM lets you handle your maintenance requests and take care of some of the repairs automatically. You can use it to log problems, keep track of labor and expenses, and record and settle your costs.

SAP PM automatically triggers processes in the other modules when needed. For instance, a repair activity may trigger a purchase order for a material in MM or purchasing.

SAP PP (SAP Production Planning and Control)

SAP PP helps businesses plan the manufacturing, sale and distribution of goods. As part of logistics, SAP PP plays an important part in a manufacturer’s supply chains.

SAP PP includes:

- Bill of material

- Capacity planning

- Material requirements planning

- Routings

What makes SAP PP tick is master data that is manipulated and stored in centralized master data tables.

Data in the master table is used to create transactional data, for example:

- Creating a purchase order in MM

- Creating a production order in PP

- Creating a sales order in SD

Example: The SAP PP production order will use master data from SAP MM to determine the raw materials needed, which will then be used to create the SAP SD sales order.

SAP PS (SAP Project System)

SAP PS is a project management tool that lets users direct funds and resources where they’re needed, and control each stage of a project to make sure it’s timely and doesn’t break the budget.

SAP PS enables project managers to set start and end dates of their projects and break them down into discrete elements and structures.

With a work breakdown structure, projects are broken down into individual tasks and linked together hierarchically, and then by processes. As a result, work packages are created, which includes activities and their details, like dates of start and ends. Additionally, the network function lets you set up relationships between different activities.

SAP QM (SAP Quality Management)

SAP QM helps you prevent defects, make continuous process improvements, and ensure quality throughout the organization.

Benefits to the organization include:

- Compliance with manufacturing quality regulations

- Improved customer service

- Reduced costs

As with any SAP ERP module, SAP QM interacts with other SAP ERP modules.

SAP QM’s main focus is quality control processes that organizations use to ensure the quality of goods through