Is SAP PLM Here to Stay? A Look at the Future of Product Lifecycle Management (2024)

Uncertain about the future of SAP PLM? Discover the trends shaping PLM (Product Lifecycle Management) … Cloud, Integrations, Digital Thread… and see if SAP remains a strong contender. Click to learn more!

Is Your Current Product Lifecycle Management (PLM) System a Clunky Relic or a Collaborative Powerhouse? The Future of SAP PLM Awaits!

Imagine this: you’re leading a product development team, racing to bring a revolutionary new gadget to market. Designers finalize blueprints, engineers tackle prototypes, and everyone scrambles to collaborate seamlessly. But then, disaster strikes! Your Product Lifecycle Management (PLM) system grinds to a halt, data silos impede communication, and delays threaten your launch deadline. In today’s fast-paced manufacturing environment, an outdated PLM system can be the Achilles’ heel of your business.

That’s why the future of SAP PLM, a long-standing industry leader, is a topic of burning interest. For many companies, SAP PLM has been the trusted steed guiding them through the complex journey of product development. But with the rise of cloud-based solutions and cutting-edge PLM trends, doubts begin to creep in: Is SAP PLM destined for the technological pasture, or can it adapt and remain a dominant force? This comprehensive guide will unravel the future of SAP PLM, equipping you with the knowledge to decide if it’s still the right stallion to ride towards manufacturing success. We’ll explore SAP PLM’s strengths and weaknesses, decipher emerging PLM trends, and compare it to cloud-based alternatives. So, fasten your seatbelts, and get ready for a deep dive into the future of SAP PLM!

The Current State of SAP PLM: A Stalwart Steed with a Few Hiccups

SAP PLM holds a prominent position in the manufacturing landscape, trusted by countless businesses for managing the entire lifecycle of their products. This dominance can be attributed to several key strengths:

- Scalability and Security: SAP PLM is built on a robust foundation, capable of handling large and complex product data sets with ease. This scalability is crucial for businesses anticipating significant growth or managing extensive product lines. Furthermore, SAP leverages industry-leading security practices to safeguard sensitive product information and comply with stringent data privacy regulations.

- Established User Base and Deep Functionality: Over the years, SAP PLM has cultivated a large and experienced user base. This translates to a wealth of resources available online, including training materials, support communities, and third-party integrations. Additionally, SAP PLM boasts a deep feature set, encompassing everything from product design collaboration and bill of materials management to engineering change order control and manufacturing process planning. This comprehensive functionality allows businesses to centralize all product-related data within a single system, streamlining workflows and enhancing operational efficiency.

However, SAP PLM also has limitations that businesses should consider:

- Potential Complexity and Cost: SAP PLM’s powerful features come at a price. The initial implementation and ongoing maintenance costs can be significant, especially for smaller businesses. Furthermore, the complexity of the platform can require specialized training for users, leading to additional investment in human resources.

- On-Premise Deployments and Integration Challenges: Traditionally, SAP PLM has been deployed on-premise, meaning businesses are responsible for hardware infrastructure and IT maintenance. While cloud-based deployment options are becoming available, on-premise deployments remain common. This can limit scalability and agility, as businesses are constrained by their own hardware resources. Additionally, integrating SAP PLM with other enterprise applications can be complex and time-consuming, hindering the creation of a truly unified digital thread across the organization.

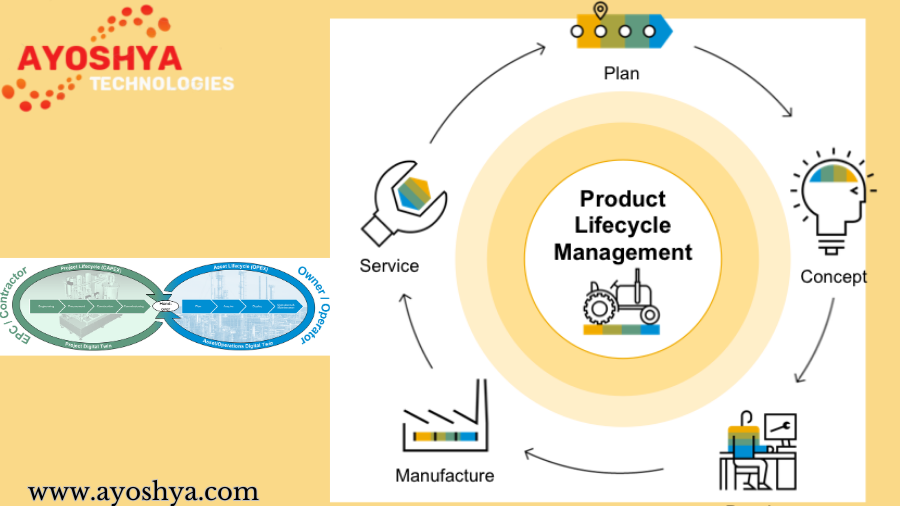

The Future of Product Lifecycle Management:

The future of PLM is brimming with innovation, driven by evolving manufacturing needs and technological advancements. Let’s explore some key trends that will likely shape the PLM landscape in the coming years:

1. Is Cloud-Based PLM the Future?

The rise of cloud-based PLM solutions is unquestionably disrupting the traditional on-premise model. Cloud-based PLM offers several advantages, including:

- Improved Scalability and Agility: Cloud-based solutions eliminate the need for expensive hardware investments and in-house IT infrastructure. This increased scalability allows businesses to seamlessly adapt their PLM capacity to fluctuating demands. Additionally, cloud-based solutions typically receive automatic software updates and benefit from the constant improvements made by the cloud provider. This ensures businesses always have access to the latest functionality and security features.

- Enhanced Collaboration and Accessibility: Cloud-based PLM facilitates real-time collaboration among teams located anywhere in the world. This global accessibility is particularly beneficial for manufacturers with distributed workforces or complex supply chains. Cloud-based solutions also improve mobile accessibility, allowing authorized personnel to access product data from any device with an internet connection.

However, cloud-based PLM also comes with considerations:

- Data Security Concerns: Migrating sensitive product data to the cloud can raise security concerns for some businesses. It’s crucial to choose a cloud provider with a proven track record of data security and compliance with relevant regulations.

- Potential Internet Connectivity Dependence: Cloud-based PLM relies on a stable internet connection. Businesses with limited or unreliable internet access may encounter disruptions to their workflows.

2. What are the Key Trends Shaping the Future of PLM?

Beyond the cloud, several other trends are poised to transform PLM:

- The Digital Thread: The concept of a digital thread encompasses the creation of a seamless flow of product data across the entire product lifecycle. This data connectivity enables businesses to gain valuable insights into product performance, facilitate predictive maintenance, and optimize manufacturing processes.

- Data Governance and Industry Data Ecosystems: As product data becomes increasingly complex and valuable, effective data governance practices become critical. PLM solutions will need to evolve to ensure data accuracy, consistency, and accessibility across the organization. Additionally, the emergence of industry data ecosystems will allow manufacturers to collaborate and share data with partners and suppliers, further enhancing innovation and efficiency.

- Integration with Advanced Technologies: PLM platforms are continuously integrating with advanced technologies like artificial intelligence (AI) and the Internet of Things (IoT). AI can automate repetitive tasks, analyze data to predict potential issues, and personalize the user experience. IoT can provide real-time data from connected products, facilitating condition monitoring and predictive maintenance.

SAP PLM: Future-Proof or on the Decline?

The future of SAP PLM hinges on its ability to adapt to the evolving PLM landscape outlined above. Here, we’ll analyze SAP’s commitment to innovation and explore the advantages and disadvantages of migrating from SAP PLM to a cloud-based solution.

1. Is SAP PLM Investing in the Future?

SAP has acknowledged the importance of cloud-based solutions and industry trends shaping PLM. Here are some indications of SAP’s commitment to future-proofing SAP PLM:

- Cloud-Based Offerings: SAP now offers cloud-based deployments of SAP PLM, providing businesses with increased scalability and agility. Additionally, SAP is continuously integrating SAP PLM with other cloud-based solutions within the SAP portfolio, facilitating the creation of a unified digital thread across the organization.

- Focus on Digital Thread and Integrations: SAP recognizes the importance of the digital thread and is developing solutions to facilitate seamless data flow throughout the product lifecycle. Additionally, SAP is investing in integrations with other enterprise applications, including engineering design tools and manufacturing execution systems (MES).

However, some critics argue that SAP may be slower to adapt than pure-play cloud PLM vendors. While SAP is making strides in the cloud arena, its legacy on-premise focus may still influence its development priorities.

2. Migrating from SAP PLM: Weighing the Pros and Cons

The decision of whether to migrate from SAP PLM depends on several factors, including your business needs, budget, and technical expertise. Here’s a balanced look at the advantages and disadvantages of migration:

- Advantages of Migrating to Cloud-Based PLM:

- Improved Scalability and Agility: Cloud-based solutions offer greater scalability and agility compared to on-premise deployments. This can be particularly beneficial for businesses experiencing rapid growth or fluctuating demands.

- Reduced IT Costs: Cloud-based PLM eliminates the need for expensive hardware investments and in-house IT maintenance. This can result in significant cost savings for businesses.

- Enhanced Collaboration and Accessibility: Cloud-based solutions facilitate real-time collaboration and improved mobile accessibility. This can be a game-changer for businesses with distributed workforces or global supply chains.

- Disadvantages of Migrating from SAP PLM:

- Migration Costs and Complexity: Migrating from SAP PLM to a new cloud-based solution can be a complex and costly process. Businesses need to carefully factor in the costs of data migration, system configuration, and user training.

- Loss of Customization: SAP PLM offers a high degree of customization. Businesses heavily reliant on customizations may find it challenging to replicate the same level of functionality in a cloud-based solution.

3. Alternative PLM Solutions

While SAP PLM remains a powerful option, several cloud-based PLM solutions are gaining traction. These solutions typically offer a more modern user interface, pre-built integrations with popular applications, and subscription-based pricing models. However, they may not offer the same depth of functionality or scalability as SAP PLM.

Conclusion:

Choosing the Right PLM Steed for Your Manufacturing Journey

Our exploration of SAP PLM revealed its strengths as a stalwart system trusted for scalability, security, and deep functionality. However, limitations like potential complexity and on-premise deployments became evident. As we peered into the future, cloud-based PLM solutions emerged as disruptive forces, promising increased agility and collaboration. We delved into key PLM trends like the digital thread and data governance, highlighting the need for future-proof PLM solutions.

So, is SAP PLM destined for the pasture, or can it adapt and remain relevant? The answer lies in SAP’s commitment to innovation. Their cloud offerings and focus on integrations demonstrate a move towards future-proofing SAP PLM. However, the decision ultimately rests with you.

Carefully consider your business needs. If scalability and agility are paramount, cloud-based PLM may be a strong contender. However, if deep customization and existing investment in SAP PLM are priorities, upgrading your current system might be worthwhile.

Don’t let your PLM system become a bottleneck in your manufacturing processes. By conducting thorough research and weighing the pros and cons outlined in this guide, you’ll be well-equipped to choose the right PLM steed to propel your business towards manufacturing success. Remember, in the ever-evolving landscape of PLM, continuous evaluation and adaptation are key to staying ahead of the curve.

you may be interested in this blog here:-

SAP Business Application Studio