Process Industry in SAP PP

Unleash the power of SAP PP for your process manufacturing needs! Dive deep into functionalities, benefits, and best practices… Craft efficiency in your production processes!

Ever feel like your production line is a chaotic cocktail of bubbling vats, whirling machines, and unpredictable outcomes? Welcome to the world of process manufacturing, where efficiency is a constant quest and consistency can feel like a fleeting dream! But fear not, fellow chemical connoisseurs, food and beverage fanatics, and pharmaceutical trailblazers! There’s a powerful weapon in your arsenal to tame the complexities of process production – SAP PP. This isn’t some flimsy beaker – SAP PP is your robust command center, a sophisticated software solution designed to bring structure, efficiency, and predictability to your process industry endeavors. So, grab your lab coat (or metaphorical equivalent) and dive deep with us as we explore the functionalities, benefits, and best practices of leveraging SAP PP to master production in the process industry.

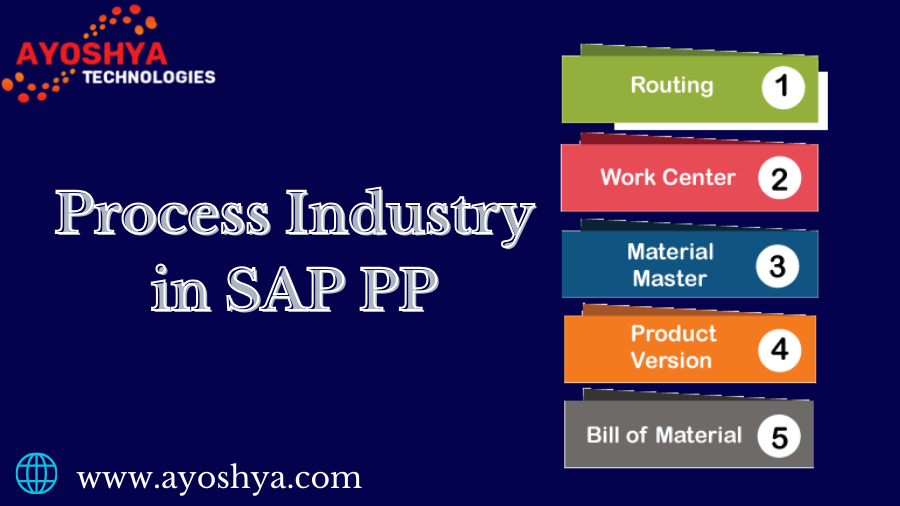

II. Core Functionalities of SAP PP for Process Industries

SAP PP acts as the central nervous system for your process manufacturing operation, offering a comprehensive suite of functionalities designed to streamline every stage of production. Let’s delve into some of the core functionalities that empower process manufacturers to achieve peak efficiency:

- Master Recipe Management: Imagine a recipe for success, but instead of flour and sugar, it involves precise instructions for mixing chemicals or brewing a batch of beer. SAP PP’s master recipe functionality allows you to define and store these production recipes in meticulous detail. You can specify ingredients (raw materials), quantities, processing times and temperatures, and even control parameters for equipment. This ensures consistency and repeatability in your production runs, a critical factor in maintaining product quality within the process industry. Additionally, SAP PP facilitates version control for recipes, enabling you to track changes and ensure everyone is working with the latest version.

- Bill of Materials (BOM) Management: Just like any recipe requires a list of ingredients, your production processes rely on specific raw materials. SAP PP’s BOM management functionality allows you to define the exact materials needed for each production recipe. This includes not only main ingredients but also co-products and byproducts, a common occurrence in process manufacturing. By meticulously managing BOMs within SAP PP, you gain precise control over material requirements, ensuring you have the right ingredients on hand to avoid production delays. Furthermore, the system can automatically generate purchase requisitions for missing materials, streamlining your procurement process.

- Production Planning and Scheduling: Gone are the days of production being a guessing game! SAP PP’s robust planning and scheduling functionalities allow you to map out your production process in detail. You can define lead times for raw materials, factor in equipment availability, and account for production capacities. The system then helps you generate realistic production schedules, ensuring on-time delivery of your products. This functionality also enables you to simulate different production scenarios, allowing you to identify potential bottlenecks and optimize your scheduling for maximum efficiency.

Advanced Features in SAP PP

The core functionalities of SAP PP provide a solid foundation for efficient process manufacturing. However, SAP recognizes that every industry has its unique needs. That’s why SAP PP offers a plethora of advanced features that can further empower process manufacturers to achieve peak performance:

- Integration with Process Control Systems: Imagine a world where your production data seamlessly flows between your SAP system and the real-time world of process control systems. This dream becomes a reality with SAP PP’s integration capabilities. By connecting to process control systems that monitor factors like temperature, pressure, and flow rates, SAP PP can receive real-time production data. This allows for continuous monitoring and adjustments to ensure your processes remain within optimal parameters, ultimately leading to improved product quality and reduced waste.

- Real-Time Production Monitoring and Reporting: In the fast-paced world of process manufacturing, having a clear picture of what’s happening on your production floor is critical. SAP PP’s advanced features go beyond static production plans, offering real-time production monitoring capabilities. You can track the progress of batches, identify potential deviations from the plan, and receive alerts if any issues arise. This empowers you to make informed decisions and take corrective actions in real-time, minimizing production disruptions and ensuring smooth operation. Additionally, SAP PP provides comprehensive production reporting tools, allowing you to analyze historical data and identify areas for further improvement.

- Sustainability Features: The process industry is increasingly focusing on environmental responsibility. SAP PP recognizes this growing need and offers features to support sustainable production practices. For instance, the system can track resource consumption (e.g., water, energy) associated with each production run. This data can be used to identify areas for optimization and implement more sustainable production processes. Additionally, SAP PP can help manage the production of co-products and byproducts, ensuring their proper disposal or utilization, minimizing environmental impact.

V. Benefits of Utilizing SAP PP in Process Industries

In the competitive world of process manufacturing, efficiency is paramount. But efficiency is more than just a buzzword – it translates to real bottom-line benefits. Implementing SAP PP in your process industry operations unlocks a treasure trove of advantages that can significantly enhance your production capabilities:

- Improved Production Planning and Scheduling: SAP PP replaces guesswork with intelligent planning. By leveraging functionalities like master recipe management and production scheduling, you can create realistic production plans that factor in material availability, equipment capacity, and lead times. This translates to on-time delivery of products, reduced production delays, and a more responsive production environment. Imagine being able to confidently quote lead times to customers, knowing you have a data-driven plan to back it up!

- Enhanced Material Management and Recipe Control: Process manufacturing relies heavily on precise control over raw materials and production processes. SAP PP’s BOM management and master recipe functionalities ensure you have the right materials on hand at the right time. The system also facilitates adherence to established recipes, promoting consistency and quality in your end products. Furthermore, SAP PP streamlines the entire material management process, allowing you to track material usage, identify potential shortages, and optimize inventory levels. This translates to reduced waste, minimized production disruptions, and cost savings associated with material procurement and storage.

- Streamlined Quality Control Processes: Maintaining consistent product quality is a cornerstone of success in the process industry. SAP PP integrates seamlessly with Quality Management (QM) modules within SAP, allowing you to establish quality control procedures directly within your production plans. The system can trigger inspections at specific points in the production process, ensuring adherence to quality standards. Additionally, SAP PP facilitates the recording and analysis of quality data, enabling you to identify areas for improvement and implement preventative measures to minimize quality defects. This translates to a more robust quality management system, increased customer satisfaction, and potentially reduced costs associated with product recalls or rework.

- What are the key differences between SAP PP and discrete manufacturing modules in SAP?

Both SAP PP and discrete manufacturing modules (e.g., SAP PP/PI) deal with production planning, but they cater to different manufacturing environments. Discrete manufacturing focuses on the production of distinct items (cars, furniture) through assembly processes. SAP PP, on the other hand, is specifically designed for process industries where raw materials are transformed or refined to create new substances (chemicals, pharmaceuticals). Key differences lie in functionalities: SAP PP offers functionalities like master recipe management and co-product handling, which are less relevant in discrete manufacturing. Ultimately, the choice between modules depends on the nature of your production processes.

FAQ

- How can I implement SAP PP for my process manufacturing business?

Implementing SAP PP is a strategic decision that requires careful planning and execution. Here’s a simplified overview of the process:

1. **Business Needs Assessment:** Identify your specific process manufacturing needs and how SAP PP can address them. Consider factors like production complexity, regulatory requirements, and integration needs.

2. **System Configuration:** Work with an SAP consultant to configure the SAP PP module to align with your specific business processes and data structures. This might involve customizing master data, workflows, and reports.

3. **Data Migration and User Training:** Migrate existing production data to SAP PP and ensure your team receives thorough training on using the system effectively. This empowers them to leverage SAP PP functionalities to their full potential.

Remember, this is a simplified view, and the implementation process can vary depending on the complexity of your business. Consulting with experienced SAP implementation partners is highly recommended to ensure a smooth and successful transition.

- What are some best practices for using SAP PP to optimize production processes?

Here are some key practices to maximize the benefits of SAP PP:

* **Maintain accurate and up-to-date master data:** Ensure your master recipes, BOMs, and material data are accurate to generate realistic production plans and optimize material management.

* **Utilize production planning and scheduling functionalities effectively:** Plan production runs well in advance, considering lead times, capacity constraints, and material availability. Simulate different scenarios to identify potential bottlenecks and optimize scheduling for efficiency.

* **Leverage real-time monitoring and reporting:** Monitor production progress in real-time to identify deviations and proactively address any issues. Utilize reports to analyze historical data and identify areas for improvement in your production processes.

By following these best practices and continuously exploring the advanced features of SAP PP, you can unlock its full potential and achieve significant improvements in your process manufacturing operations.

Conclusion

The tide is turning in the world of process manufacturing. No longer do you have to navigate the chaotic seas of production with outdated methods. SAP PP emerges as your lighthouse, guiding you towards a future of efficiency, predictability, and optimized production processes. We’ve explored the core functionalities of SAP PP, from master recipe management to production planning and scheduling. We’ve unveiled the power of advanced features like real-time monitoring and integration with process control systems. And most importantly, we’ve highlighted the tangible benefits – improved quality control, reduced waste, and ultimately, a stronger bottom line.

Remember, SAP PP is a powerful tool, but its true potential lies in your hands. By understanding its functionalities, implementing best practices, and continuously exploring its capabilities, you can transform your process manufacturing operations. So, take the first step towards a smoother, more efficient production journey. Consult with SAP experts, assess your needs, and embark on your SAP PP implementation. With the right planning and a commitment to leveraging this robust solution, you’ll be well on your way to mastering production in the process industry. Just a gentle reminder, stay up-to-date with the ever-evolving SAP landscape to ensure you’re always harnessing the latest functionalities for peak process manufacturing efficiency. Now set sail and conquer those production challenges – smooth seas and happy manufacturing await!

you may be interested in this blog here

Json to internal table in sap abap